High Permeability Y3 Motor Laminations for Industrial Motor Performance

Industry Background and Market Demand

Industrial motors form the backbone of manufacturing, energy, and processing sectors, consuming a substantial portion of global electricity. As companies face increasing pressure to reduce energy consumption and operating costs, the performance and efficiency of motors have become critical factors. One key component influencing motor efficiency is the magnetic core, specifically the laminations used in stators and rotors. High-permeability Y3 motor laminations have gained attention for their ability to enhance magnetic flux conduction, reduce core losses, and support high-efficiency motor designs across diverse industrial applications.

Core Concepts and Technical Overview

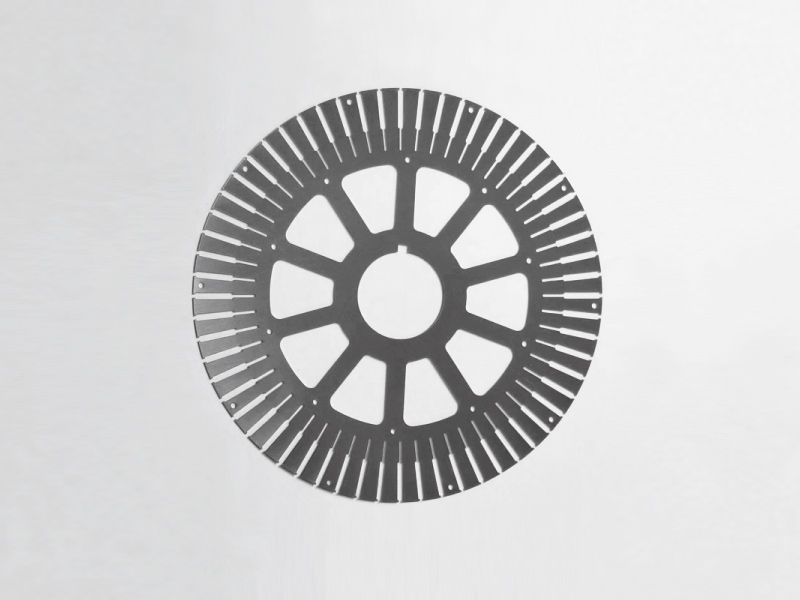

Motor laminations are thin, stacked sheets of electrical steel that form the core of electric motors. Their primary function is to direct magnetic flux while minimizing energy losses due to hysteresis and eddy currents. High permeability laminations, such as the Y3 series, allow magnetic flux to pass more efficiently, reducing energy dissipation and improving overall motor performance. By optimizing material properties and lamination geometry, Y3 laminations ensure stable torque, lower vibration, and improved thermal performance, making them ideal for industrial motors operating under heavy load or continuous duty cycles.

Structure, Materials, and Manufacturing Process

Y3 motor laminations are typically fabricated from high-grade silicon steel, selected for its high magnetic permeability and low core loss characteristics. Thickness ranges from 0.35 mm to 0.50 mm, balancing magnetic efficiency with mechanical strength. Manufacturing begins with precision cutting or stamping to maintain tight dimensional tolerances, followed by annealing to relieve internal stress and enhance magnetic properties. A uniform insulating coating is applied to each lamination to suppress inter-laminar eddy currents. The combination of material selection, cutting precision, and surface treatment ensures consistent performance across the entire motor core assembly.

Factors Affecting Quality and Performance

Several factors influence the effectiveness of Y3 laminations. Material purity and silicon content directly affect magnetic permeability and core loss. Dimensional accuracy is critical; variations in tooth width, stacking height, or lamination profile can disrupt flux distribution, causing noise, vibration, and reduced efficiency. The quality of the insulating coating is equally important, as uneven coverage can lead to localized eddy current losses. Additionally, the stacking process must maintain tight tolerances to prevent deformation, misalignment, or magnetic leakage, which could compromise motor reliability under industrial operating conditions.

Supply Chain and Supplier Selection

Selecting a reliable supplier is vital to ensure consistent lamination quality. Suppliers should provide detailed material certifications, including magnetic properties, silicon content, and mechanical tolerances. Experience in precision stamping, annealing, and coating processes is essential. Supply chain stability, including the ability to deliver high volumes without compromising quality, is a key consideration for industrial motor manufacturers. Partnerships with reputable suppliers reduce production risks, support quality assurance, and ensure that motors meet energy efficiency standards.

Common Industry Challenges

Despite advances in manufacturing, several challenges persist. Stamping thin laminations without causing warping or edge burrs remains difficult. Inconsistent coating thickness can increase inter-laminar losses, while improper stacking may lead to misalignment and uneven flux paths. Additionally, the trade-off between reducing lamination thickness to minimize losses and maintaining sufficient mechanical strength requires careful engineering. These challenges underscore the importance of precision manufacturing, rigorous quality control, and careful material selection.

Applications and Industry Use Cases

High-permeability Y3 laminations are widely used in industrial motors powering pumps, compressors, conveyors, and HVAC systems. In energy-intensive facilities, replacing standard laminations with Y3 laminations can reduce core losses by up to 10–15%, translating to measurable electricity savings. In high-speed motors used for processing lines, Y3 laminations contribute to stable torque output, lower operating temperatures, and extended motor life. They are also increasingly applied in renewable energy systems, such as wind turbines, where efficiency and durability are critical.

Trends and Future Developments

The demand for higher-efficiency industrial motors continues to drive innovation in lamination technology. Future developments include ultra-thin laminations with improved insulating coatings, advanced silicon steel formulations with higher saturation flux densities, and grain-oriented laminations for optimized magnetic performance. Automation in manufacturing, such as laser cutting and robotic stacking, is enhancing precision and reducing variability. Additionally, as industrial energy standards become stricter, the adoption of high-permeability laminations like Y3 will be increasingly essential for compliance and operational cost reduction.

FAQ / Key Considerations

Why is high permeability important for industrial motor laminations?

Higher permeability reduces magnetic reluctance, improving efficiency and torque stability.

How does lamination thickness affect performance?

Thinner laminations reduce eddy current losses but require careful handling to prevent deformation.

What industries benefit most from Y3 laminations?

Energy-intensive sectors, manufacturing, HVAC systems, and renewable energy applications all gain efficiency and reliability advantages.

Conclusion

High-permeability Y3 motor laminations are a critical element in designing energy-efficient and reliable industrial motors. Their precise geometry, optimized material properties, and careful manufacturing directly impact motor performance, energy consumption, and operational longevity. As industrial demands and energy regulations evolve, Y3 laminations will remain a key component for high-performance motor cores across multiple sectors.

Авторское право © Чжэцзянская компания электромеханических технологий Синьчжэн. Все права защищены.

Этот веб-сайт использует файлы cookie, чтобы обеспечить вам максимально эффективное использование нашего веб-сайта.

Комментарий

(0)